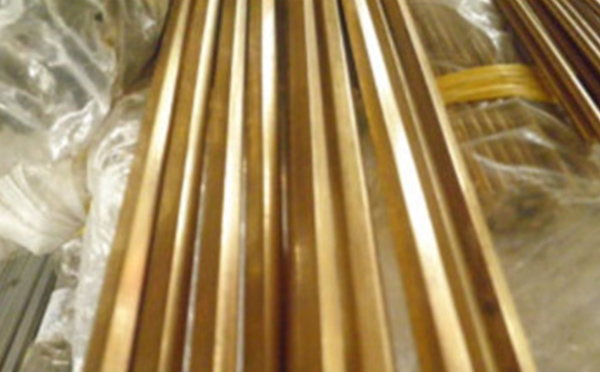

Section bar

We use the #59 brass section bar as the lock body, which can be proved the Material. As usual, we will customize the size of kinds of brass padlock, according the clients detail requirement, from 15mm to 75mm, all of them we can offer, even the specific size and sharp. We have enough confidence to finish the production follow the stander.

Stamping

In our factory we have kinds of the stamping machines from 15 tons to 120 tons. Total investment is more than two million. In order to reduce the cost and spend the production, our stamping uses the high speed stamping. Gather the step of the stamp molds from 5 sets to 1 set. One side, it help us to reduce the cost, and in the other side, it helps us to speed of production.

Polished Machine

We have more than 5 sets of the polished machines. As known, the treatment of the brass padlock, it is really important as human’s face. In the other site, the quality of the treatment for the surface, depended of the quality level, mat polish, mirror polish, both of them we can do, full-automatic of polishing the brass padlocks body.

Assemble

Worker’s No: more than 50 people

We have more than 50 people of 5 years’ experience of assembling. They are the team of our factory. 5 assembly line, testing, packing, each step we will have the person who responsible.

In that case, we can keep the FTQ at 98%.